The M12 fisheye lens is a fisheye lens with an M12 mount. It features a compact design, a wide field of view, and high resolution, making it suitable for special scenarios in industrial inspection that traditional lenses struggle to handle. It has irreplaceable application advantages.

The special applications of M12 fisheye lenses in industrial inspection are mainly reflected in the following aspects:

1.Large-scale, one-time coverage testing

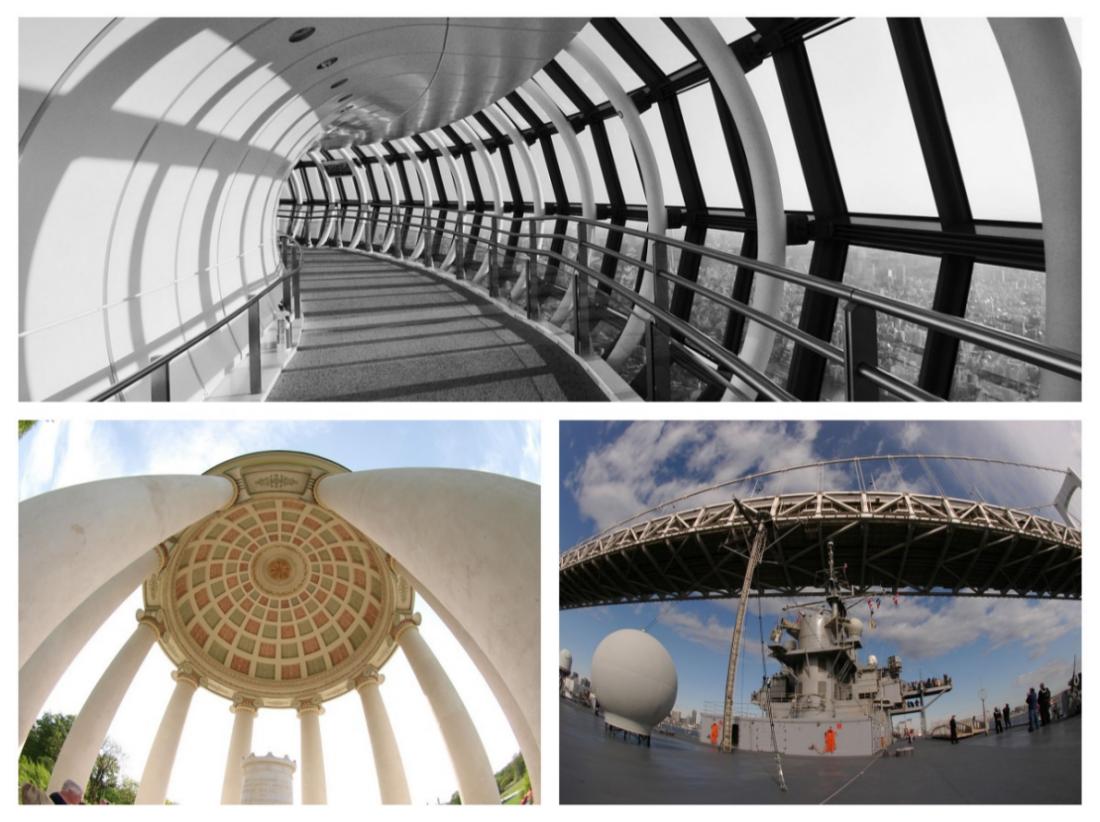

The M12 fisheye lens provides an ultra-wide-angle field of view, typically covering more than 180 degrees, and even up to 220° or more. A single shot can cover a vast area, eliminating the need to move the lens or adjust the robotic arm, thus capturing the complete field of view, improving inspection efficiency, and avoiding stitching errors, while also saving on hardware costs.

For example, when monitoring the overall operating status of large production lines or CNC machine tools, the M12 fisheye lens can capture a complete view of the equipment in a single shot, quickly identifying any misplaced components or foreign objects.

2.Internal inspection of confined spaces

The compact M12 fisheye lens can be easily integrated into tight industrial structures, while its ultra-wide-angle or even panoramic field of view allows a single image to cover the entire circumference of pipes and container walls that conventional lenses cannot reach, enabling efficient detection of defects such as cracks and dents.

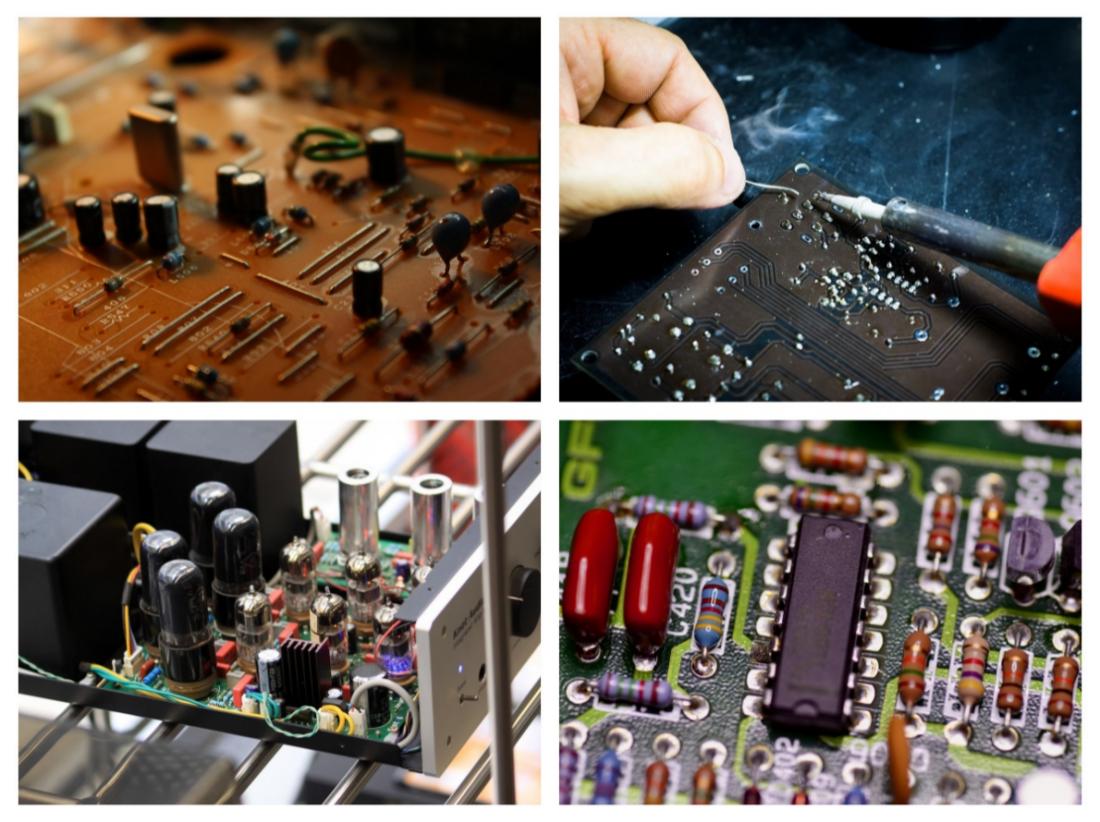

For example, in confined workspaces such as electronic component soldering and miniature parts assembly, the fisheye lens can capture the integrity of solder joints and the proper assembly of parts with its ultra-wide angle, preventing missed detections. Inside precision components such as motors and gearboxes, the fisheye lens can monitor critical areas such as gear meshing and bearing operation, helping to identify wear and jamming problems.

The M12 fisheye lens is suitable for internal inspection in confined spaces

3.Close-up and multi-angle observation

At extremely close working distances, the M12 fisheye lens still provides an ultra-wide field of view, covering a vast area in a single shot, making it suitable for rapid spatial screening.

For example, a fisheye lens can be used to photograph the entire circuit board in a confined space, quickly locating abnormal areas; it can also be inserted through small openings to inspect the interior of machinery, such as observing the inside of an engine for anomalies.

4.Curved surface/cylinder detection

For objects with special specifications such as curved surfaces and cylinders, a fisheye lens can capture the entire surface and all parts of the workpiece in a single circular shot, avoiding the need to rotate the workpiece or use multiple cameras, thus allowing for the detection of defects or anomalies. For example, a fisheye lens can be used to photograph the entire surface of a tire in a circular manner to check for any abnormalities.

Fisheye lenses can capture the surface of objects in a circular manner

5.Industrial robot navigation

The compact M12 fisheye lens can be mounted on AGVs (Automated Guided Vehicles) and mobile robots. Combined with panoramic stitching algorithms, it can create a 360° environmental map of the surroundings, enabling seamless panoramic monitoring without blind spots. This provides robotic arms with a wide field of environmental perception, facilitating obstacle avoidance and path planning, and improving the accuracy of object recognition, localization, and grasping.

For example, a robot equipped with a fisheye lens can monitor obstacles in real time in narrow workshops or production lines, enabling safe obstacle avoidance.

Furthermore, due to the complex industrial environment, the following issues need to be considered when using M12 fisheye lenses in practical applications:

(1)Fisheye distortion problem

Fisheye lenses are susceptible to barrel distortion, which causes straight lines at the edges of the image to appear curved. In scenarios requiring precise measurements, this distortion must be corrected using image correction algorithms to ensure the accuracy of the detection results. Before use, you should confirm the distortion rate of the fisheye lens and verify that your detection software supports a fisheye distortion correction model.

When using a fisheye lens, you need to pay attention to distortion issues

(2)Image sensor matching problem

To ensure that the lens’s image circle covers the size of the camera sensor, otherwise severe vignetting will occur in the image. To maximize the wide-angle view of the fisheye lens, it is recommended to pair it with an image sensor with an aspect ratio close to 1:1 or 4:3 (such as IMX250, IMX334, etc.), and avoid using a 16:9 sensor to prevent wasting effective pixels.

(3)Environmental adaptability

It’s important to consider the lens’s operating temperature range and features such as dust resistance (IP rating) to ensure stable operation in the working environment.

Overall, the M12 fisheye lens, with its advantages of small size, ultra-wide field of view, and high resolution, has become a key component in industrial vision systems and is widely used in various industrial inspection scenarios such as large-area inspection, confined space inspection, and robot navigation.

Final Thoughts:

ChuangAn has carried out the preliminary design and production of fisheye lenses, which are widely used in various fields. If you are interested in or have needs for fisheye lenses, please contact us as soon as possible.

Post time: Feb-06-2026