As a special optical lens, telecentric lens is mainly designed to correct the parallax of traditional lenses. It can maintain a constant magnification at different object distances and has the characteristics of low distortion, large depth of field, and high imaging quality.

The high-precision imaging quality of telecentric lenses is crucial to industrial production and plays an important role in precision measurement and automated inspection systems. Therefore, telecentric lenses have irreplaceable application advantages in the field of industrial automation.

1.High-precision measurement and inspection

Telecentric lenses, through their parallel optical path design, eliminate parallax and maintain a constant image magnification within a certain object distance range, enabling high-precision dimensional measurement.

They are widely used in precision measurement. They can accurately measure part dimensions, including length, width, and diameter, at long distances and are often used to monitor the accuracy and consistency of part dimensions during the production process.

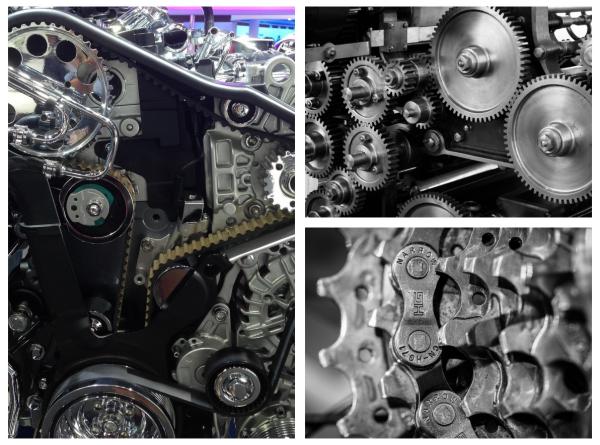

For example, in dimensional inspection of mechanical parts, electronic components, and plastic parts, telecentric lenses ensure accurate micron- and even nanometer-level measurements in diverse working environments, avoiding errors caused by parallax or distortion.

Telecentric lenses are often used for high-precision measurement and inspection

2.Robot vision guidance and positioning

Telecentric lenses can reduce image distortion caused by surface tilt or height differences, assisting 3D vision systems in accurately identifying object positions. They are widely used in machine vision systems, such as for the precise positioning and navigation of industrial robots.

In automated navigation systems, telecentric lenses can be used for long-distance, real-time imaging and recognition of the environment, enabling robots and unmanned vehicles to achieve precise navigation and obstacle avoidance, enabling tasks such as automated operation, path planning, and material handling.

For example, the stable image information provided by telecentric lenses enables robots to accurately identify and locate target objects, enabling them to quickly and accurately complete tasks such as assembly, cutting, and sorting.

3.Surface defect detection

Telecentric lenses are insensitive to light angles and can maintain image contrast even in complex lighting conditions, making them suitable for detecting subtle defects. They are often used to detect surface flaws, leaks, and deformation in products, playing a vital role in surface quality inspection for mobile phone components, plastic parts, and automotive parts.

For example, they are used to identify solder defects (cold solder joints, short circuits) on PCBs and detect scratches, pits, and rust on metal surfaces. In mobile phone screen inspection, telecentric lenses can effectively resolve dark areas and color discrepancies between screen borders and interfaces, improving inspection efficiency and accuracy.

Telecentric lenses are often used for surface defect detection

4.Online detection and non-contact measurement

Telecentric lenses enable non-contact measurement of distant objects and are widely used in industrial online inspection systems to detect critical dimensions and surface defects in workpieces. They can also monitor equipment position, motion trajectory, and temperature, enabling safe and accurate measurement of objects that are difficult to access or in high-temperature, high-pressure environments.

For example, in fields such as food packaging, pharmaceutical testing, and automotive parts manufacturing, telecentric lenses can quickly and accurately detect surface flaws and dimensional deviations without physical contact, significantly reducing inspection costs while improving production efficiency.

5.Logistics sorting and item identification

Telecentric lenses can reduce motion blur and, when used with high-speed cameras, can capture clear images of fast-moving objects. This allows for real-time detection of surface defects on high-speed sorting lines. They can also be used in logistics sorting systems to automatically identify and sort items, optimizing handling processes.

For example, through their high depth of field and low distortion, telecentric lenses can clearly capture the three-dimensional outline of an object, enabling efficient object identification and classification.

Telecentric lenses can be used for logistics sorting and object identification

6.Food and drug packaging inspection

On packaging production lines, telecentric lenses can be used to inspect package integrity and label accuracy. Their high resolution and low distortion ensure high-precision and reliable packaging inspections.

For example, they can be used to inspect food and pharmaceutical packaging boxes and bottles for damage, misalignment, and defects, ensuring that packaging quality meets standards.

7.Special industrial scene applications

Telecentric lenses are also used in some special industrial scenarios, such as textile fiber quality inspection and metal parts thread processing inspection. For example, in textile inspection, telecentric lenses can evaluate fiber diameter, texture and textile quality.

Telecentric lenses are also used in some special industrial scenarios

In addition, with the development of science and technology, the application scenarios of telecentric lenses will continue to expand. For example, in the fields of virtual reality (VR) and augmented reality (AR), telecentric lenses can be used to achieve higher-quality image acquisition.

In summary, telecentric lenses, thanks to their high precision, low distortion, and constant magnification, have been widely used in industrial automation. As core components of high-precision vision systems, they provide strong technical support for improving production efficiency and optimizing product quality, whether in precision measurement, defect detection, robotic vision guidance, or logistics sorting. They have become a crucial tool for companies pursuing automation and digital upgrades.

Final Thoughts:

If you are interested in purchasing various types of lenses for surveillance, scanning, drones, smart home, or any other use, we have what you need. Contact us today to learn more about our lenses and other accessories.

Post time: Oct-31-2025