Due to its features of non-destructive testing, high-precision imaging, and flexible operation, industrial endoscopes have become the “invisible doctor” for equipment inspection in the energy industry and are widely used in multiple energy fields such as oil and gas, electricity, wind power, and hydropower.

The lens is an important component of industrial endoscopes and a key link in their function. Industrial endoscope lenses are widely used in the energy industry, mainly in equipment inspection, maintenance, and fault diagnosis, helping to improve equipment operating efficiency, reduce downtime, and ensure safety.

In general, the specific applications of industrial endoscope lenses in the energy industry include but are not limited to the following:

1.Oil and gas industry

Industrial endoscope lenses are widely used in the oil and gas industry, mainly for pipeline inspection, storage tank inspection, downhole equipment inspection, valve and pump body inspection, etc.

For example, during pipeline inspection, industrial endoscopes can detect corrosion, cracks, deposits, or weld defects within oil/gas pipelines, minimizing the risk of leaks or ruptures and ensuring safe pipeline operation. During tank inspections, they focus on bottom corrosion, weld quality, or scaling within reactors, minimizing downtime for maintenance.

Industrial endoscope lenses are widely used in the oil and gas industry

2.Power industry

Industrial endoscopes are primarily used in the power industry for the inspection of boilers and steam turbines, transmission lines and transformers, and nuclear power plant equipment.

For example, in boilers, they are used to detect coking, corrosion, or wear within water-wall tubes and superheaters to ensure thermal efficiency and operational safety. In steam turbines, they are primarily used to inspect cracks or foreign object blockage within turbine blades to prevent unplanned downtime. In nuclear power plants, they are primarily used to inspect the operating status of key equipment, such as the internal components of the reactor pressure vessel (such as the control rod drive mechanism) and the cooling system, to ensure nuclear safety.

3.Wind energy industry

Industrial endoscope lenses are used in the wind energy industry, mainly to inspect wind turbine blades, gearboxes and bearings, and the inside of towers. By capturing high-definition images, engineers can quickly identify potential issues and make repairs, ensuring the proper functioning of the equipment.

For example, industrial endoscopes are used to inspect the internal structure of wind turbine blades, assessing cracks, corrosion, and damage to extend their service life. They can also be used to perform endoscopic inspections of welds on high-altitude towers, preventing structural cracking caused by weld defects while also minimizing the risks of working at height.

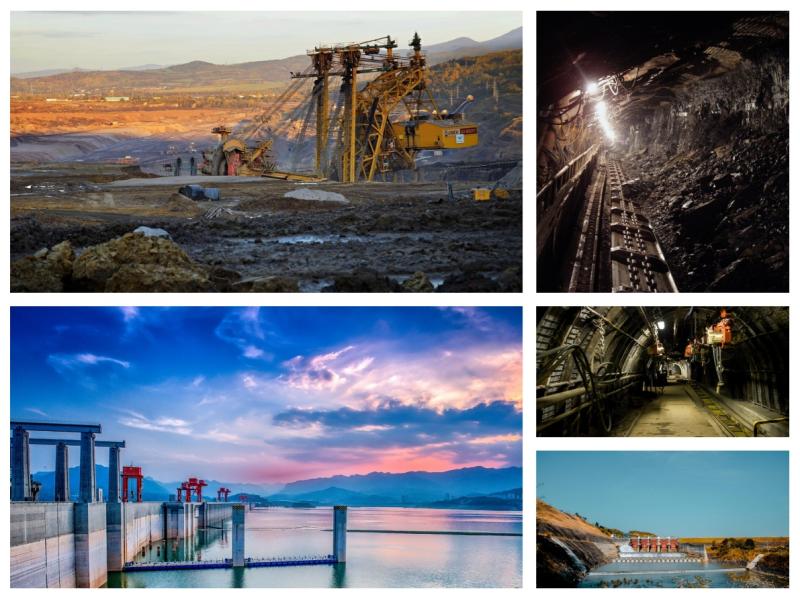

Industrial endoscope lenses are commonly used in the power and wind energy industries

4.Hydropower industry

The application of industrial endoscope lenses in the hydropower industry is mainly aimed at underwater inspection of key equipment such as turbines and penstocks.

For example, for turbine inspection, the turbine blades can be checked for wear, cracks or foreign matter to ensure the normal operation of the equipment; for pressure pipe and valve inspection, it is mainly used to check the internal conditions of pressure pipes and valves, and evaluate problems such as corrosion, cracks or blockage, thereby ensuring the safe and stable operation of the power station.

5.Coal and mining

In the coal industry, industrial endoscope lenses are primarily used for inspection, diagnosis, and maintenance of mining equipment and ventilation systems.

For example, for mining equipment inspection, they are primarily used to check the internal condition of mining equipment (such as drill bits and conveyor belts) and assess wear or damage. For ventilation system inspection, they primarily examine the internal condition of mine ventilation ducts to ensure proper functioning. If equipment cannot be disassembled, an endoscope can be used to inspect internal issues and quickly locate faults.

Industrial endoscope lenses are commonly used in hydropower and coal mining industries

6.Solar industry

Industrial endoscope lenses are used in the solar energy industry, mainly for the inspection of photovoltaic modules, solar collectors, etc. For example, in photovoltaic modules, industrial endoscope lenses are primarily used to inspect the connection wires and cell conditions inside the module to assess for damage or aging issues. They can also be used to inspect pipes, welds, and corrosion inside collectors to ensure efficient system operation.

In addition, industrial endoscope lenses can be used to detect environmental pollution and energy waste in the energy industry. For example, they can monitor waste gas emissions from sewage outlets, chimneys, etc. in real time, which helps protect the environment and personnel health.

In short, through non-destructive testing technology, industrial endoscope lenses can help technicians quickly discover defects and problems inside the equipment, thereby improving the safety and reliability of the equipment, extending the life of the equipment, and reducing downtime. It has become an indispensable tool in the energy industry and has a wide range of important application scenarios.

Final Thoughts:

By working with professionals at ChuangAn, both design and manufacturing are handled by highly skilled engineers. As part of the purchasing process, a company representative can explain in more detail specific information about the type of lens you wish to purchase. ChuangAn’s series of lens products are used in a wide range of applications, from surveillance, scanning, drones, cars to smart homes, etc. ChuangAn has various types of finished lenses, which can also be modified or customized according to your needs. Contact us as soon as possible.

Post time: Nov-14-2025