Non-destructive testing (NDT) is a non-destructive testing method that inspects objects without causing damage. It is a crucial testing method in the industrial field and plays a vital role in industrial development. Machine vision lenses are widely used in industrial production; their high resolution, precise imaging, and specialized optical designs meet the needs of industrial inspection, and their application in NDT is equally significant.

In nondestructive testing, the specific applications of machine vision lenses include, but are not limited to, the following:

1.Surface defect detection

In industrial production, machine vision lenses are commonly used to inspect the surfaces of materials such as metals, plastics, glass, and ceramics for defects such as scratches, cracks, pores, and inclusions, ensuring that product quality meets requirements. Through their high-resolution and low-distortion imaging capabilities, machine vision lenses can clearly display these surface defects, providing reliable data support for subsequent image processing and analysis.

For example, a high-resolution machine vision lens paired with a microscope or a high-frame-rate camera can capture micron-level defects, such as identifying poor solder joints, short circuits, and component misalignment on PCB boards, or scratches and contaminants on semiconductor wafer surfaces.

2.Internal defect/structural inspection

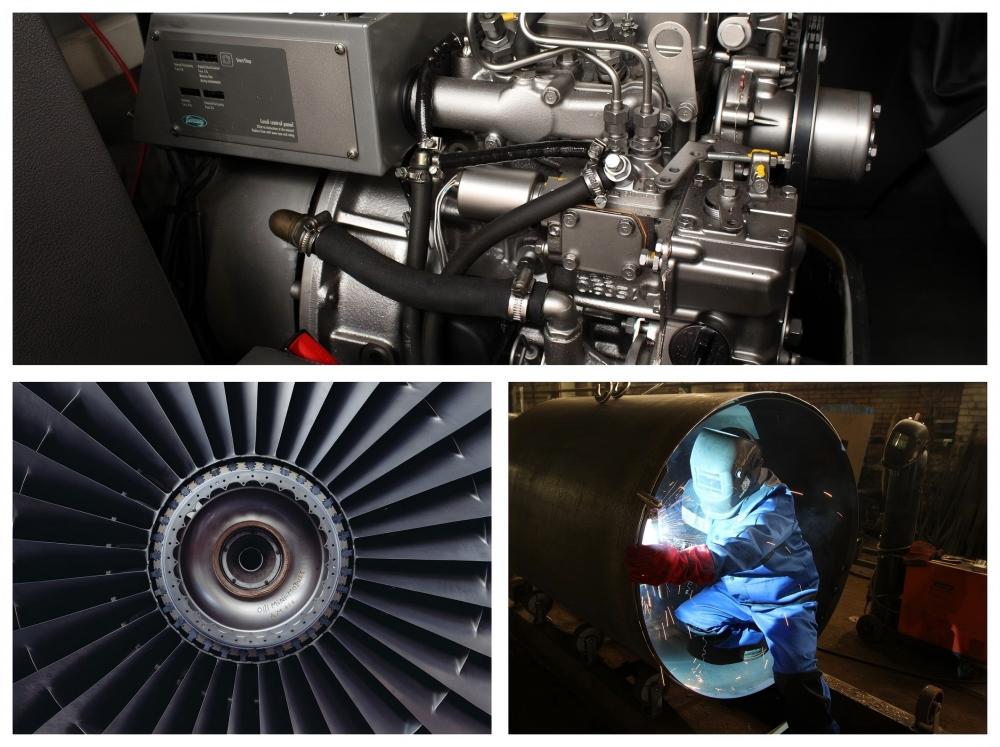

By using machine vision lenses combined with special optical techniques, it is possible to indirectly observe the internal structure or defects of objects. This allows for the detection of hidden defects such as pores, delamination, and cracks in castings, composite materials, and welded joints.

For example, it can detect bubbles, impurities, and cracks inside glass, plastics, and optical components (such as glass bottles and optical fiber preforms). Through backlight imaging or laser scanning, it can detect delamination or debonding within multi-layered structures (such as aerospace composite material components).

Machine vision lenses are commonly used for product defect detection

3.Precision measurement of dimensions

Machine vision lenses are frequently used for precision dimensional measurement and form and position tolerance verification of products, such as semiconductor wafer thickness, bearing roller roundness, and product appearance and color. For example, on food filling lines, machine vision lenses can be used to check the sealing of bottle caps and the correctness of labels, ensuring product quality and safety.

4.Automated production inspection

The application of machine vision lenses in non-destructive testing also includes automated production inspection, which is often used for automated defect screening on high-speed production lines, such as automatic inspection of electronic chips, lithium batteries, automotive weld seams, etc.For example, a line-scan lens can be used with a high-speed camera to scan the surface defects of a steel plate line by line to achieve high efficiency detection.

5.Inspection of pipes/confined spaces

Machine vision lenses are used in industrial endoscopes to detect defects inside complex structures, such as hidden defects inside engines, pipe walls, or welds. For example, industrial video endoscopes use long, flexible probes to penetrate deep into equipment, transmitting high-definition images in real time, enabling non-destructive testing without disassembly.

Machine vision lenses can be used to detect defects inside complex structures

6.Detection under special conditions

Machine vision lenses can also be used for remote inspection in harsh environments such as high temperature, high pressure, and radiation, including nuclear reactors and oil refinery pipelines, enabling inspections that are difficult to perform using conventional methods.

For example, high-temperature resistant lenses can be used to inspect surface defects of steel billets inside steelmaking furnaces or damage to equipment sealing surfaces under high pressure. By mounting miniature machine vision lenses on endoscopes, corrosion and weld cracks on the inner walls of pipelines can be detected, such as in petrochemical pipelines and nuclear reactor containers.

In summary, machine vision lenses, with their advantages of high-resolution imaging, non-contact measurement, and strong real-time performance, have become a key technology in modern industrial quality control. Their core value lies in improving imaging quality and quantifying defect information, thereby enhancing the reliability of industrial inspection and playing an irreplaceable role in non-destructive testing.

Final Thoughts:

ChuangAn has carried out the preliminary design and production of machine vision lenses, which are used in all aspects of machine vision systems. If you are interested in or have needs for machine vision lenses, please contact us as soon as possible.

Post time: Dec-12-2025