The M12 low distortion lens features a standardized interface, compact size, and low distortion, providing high image quality with clear details. It has a wide range of applications in industrial inspection.

In industrial inspection, the advantages of using M12 low-distortion lenses are mainly reflected in the following aspects:

1.Lightweight and compact, easy to integrate

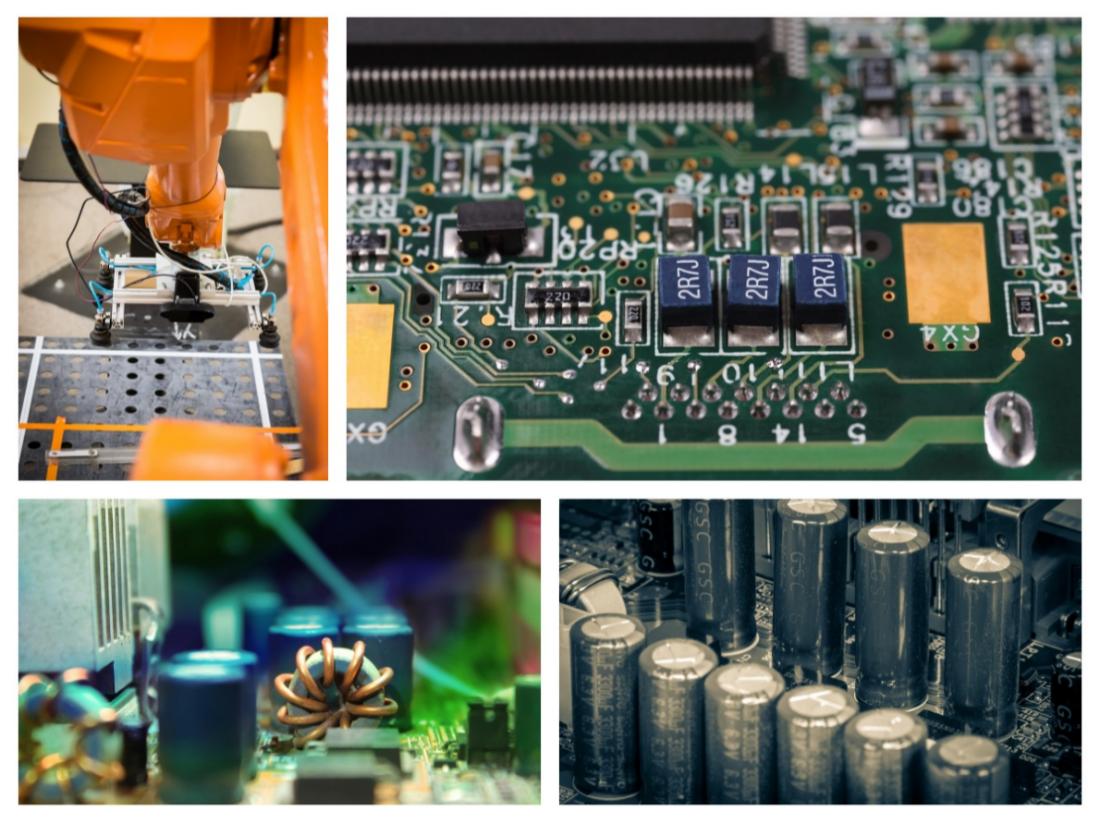

The M12 low distortion lens features a compact M12 standard threaded interface design, making it small and lightweight. It is easy to integrate into space-constrained equipment such as vision-guided robotic arms, small inspection machines, and conveyor belts, offering flexible installation and making it ideal for automated production lines.

2.High-precision imaging

The low-distortion design of the M12 low-distortion lens ensures the authenticity and accuracy of the provided images, reducing measurement errors caused by lens distortion, which is crucial for industrial applications that require precise measurement and inspection. Furthermore, this low-distortion performance allows the lens to capture the complete image of an object even at close range, eliminating the need for frequent adjustments to the shooting distance.

The M12 low distortion lens provides high-precision imaging

3.Ensure measurement accuracy

Distortion can lead to dimensional errors and geometric distortion, causing straight lines at the image edges to appear curved. M12 low-distortion lenses control distortion to extremely low levels (typically <1%, or even <0.1%) through superior low-distortion design, significantly reducing detection errors and ensuring the accuracy and reliability of measurement results.

For example, in applications such as robotic grasping and PCB board positioning, M12 low-distortion lenses can ensure the accuracy of coordinate calculations, preventing grasping deviations or positioning errors caused by image distortion.

4.Strong environmental adaptability

M12 low distortion lenses typically utilize wear-resistant materials and protective coatings, offering excellent durability and a long lifespan. They can maintain stable operation over extended periods in harsh industrial environments with varying temperatures, humidity, and vibrations, thereby improving system reliability.

The M12 low distortion lens has strong environmental adaptability

5.Available in various focal lengths to suit a variety of sensors

From wide angle to medium telephoto, the M12 low-distortion lenses offer a variety of focal lengths to suit different working distances and scene requirements. The M12 interface is also compatible with mainstream machine vision cameras and line scan cameras, supporting various sensor sizes from 1/3″ to 1/1.8″, facilitating quick integration and replacement.

6.It has a significant cost advantage

As an industrial standard component, M12 lenses are produced on a large scale, and their costs have been effectively controlled. Although low-distortion lenses are more expensive than ordinary M12 lenses, the cost advantage of M12 low distortion lenses is very significant compared to traditional large-sized low-distortion lenses or other high-end custom lenses.

In short, while meeting accuracy requirements, M12 low-distortion lenses provide a practical and cost-effective solution, significantly reducing overall system costs during large-scale deployment.

M12 low distortion lenses offer a significant cost advantage

7.It has outstanding advantages in specific scenarios

The advantages of M12 low-distortion lenses are particularly prominent in specific industrial inspection scenarios. For example, in electronic component inspection, such as inspecting solder joints and chip pins on a PCB board, accurate judgment of spacing and shape is required. Low distortion prevents the pins from appearing distorted visually, reducing misjudgments.

In scenarios such as robotic arm grasping and parts assembly, the lens needs to accurately reproduce the object’s position and angle. Using a low-distortion lens avoids positioning errors caused by image distortion, improving the accuracy of automated assembly.

In summary, the M12 low distortion lens, with its low distortion, high resolution, compact size, and strong environmental adaptability, is an ideal optical component for various industrial inspection scenarios. It helps improve inspection accuracy, simplify system design, and reduce production costs.

Final Thoughts:

ChuangAn has carried out the preliminary design and production of M12 low distortion lenses, which are widely used in various fields. If you are interested in or have needs for M12 low distortion lenses, please contact us as soon as possible.

Post time: Jan-16-2026