Amalensi ezimbonizisetshenziswa kabanzi. Ngaphezu kokusetshenziswa kwazo ekuhlolweni kwezimboni, ukuqapha ezokuphepha, i-3C electronics kanye neminye imboni, zisetshenziswa kabanzi embonini ye-PCB (Printed Circuit Board).

Iziqondiso ezithile zokusetshenziswa kwamalensi ezimboni embonini ye-PCB

Ukusetshenziswa okuqondile kwamalensi ezimboni embonini ye-PCB kungafingqwa ngalezi zindlela ezilandelayo eziyinhloko:

1.Ukukhiqizwa okuzenzakalelayo

Amalensi ezimboni ahlanganiswe nezinhlelo zokubona komshini angasetshenziswa emishinini ezenzakalelayo emigqeni yokukhiqiza ye-PCB, njengamarobhothi okushisela okuzenzakalelayo, imishini yokubeka, njll., ukuze kufezwe ukutholwa, ukufakwa kanye nokucutshungulwa okuzenzakalelayo emigqeni yokukhiqiza ye-PCB.

Amalensi ezimboni anganikeza izithombe ezicacile, okwenza uhlelo lwerobhothi lukwazi ukuhlonza nokucubungula ulwazi ngokunembile nangokushesha njengendawo yamabhodi e-PCB kanye nokuhlelwa kwezingxenye, ngaleyo ndlela kufezwe inqubo yokukhiqiza ezenzakalelayo esebenza kahle.

2.Ukuhlolwa nokulawulwa kwekhwalithi

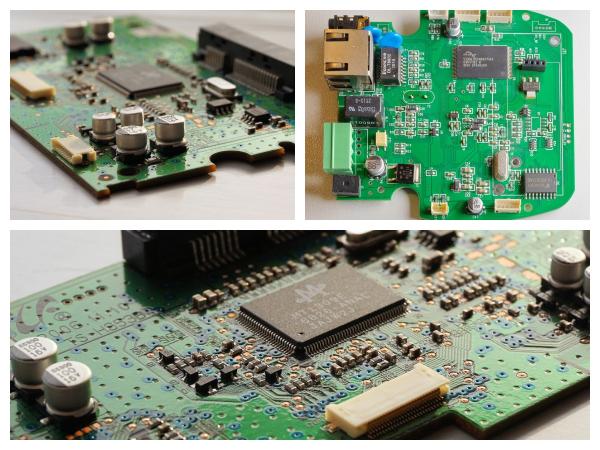

Embonini ye-PCB,amalensi ezimbonizisetshenziswa kabanzi ukuthola nokuhlola ikhwalithi nobuqotho bamabhodi e-PCB. Ngokucaca okuphezulu nokucaca kwamalensi okukhanya, ikhwalithi yamalunga e-solder, izikhundla zezingxenye, amaphutha kanye namaphutha kuma-PCB kungatholakala ukuqinisekisa ikhwalithi yomkhiqizo nokuthembeka.

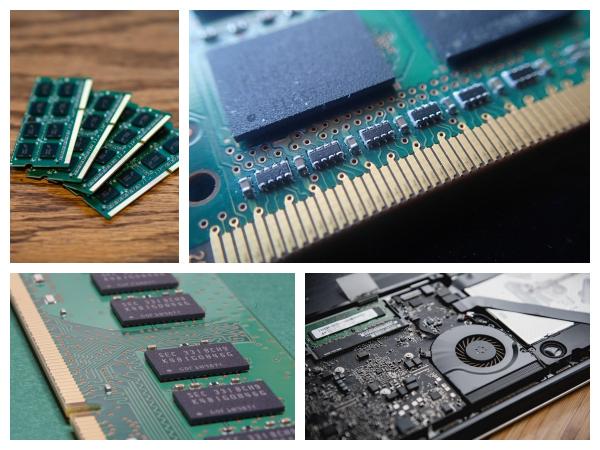

Amalensi ezimboni asetshenziswa embonini ye-PCB

3.Indawo eqondile kanye nokulinganisa

Enqubweni yokukhiqiza embonini ye-PCB, amalensi ezimboni angasetshenziswa ukuthola ngokunembile izingxenye kanye namaphuzu okuxhuma ku-PCB, kanye nokuwalinganisa nokuqinisekisa ukuqinisekisa ukunemba nokunemba kokufakwa kanye nokuxhumeka kwezingxenye.

Isibonelo, ezinqubweni ezifana nokubhoboza i-PCB kanye nokushisela iminwe yegolide, indawo idinga ukulawulwa ngokunembile. Amalensi ezimboni anganikeza izithombe ezicacile nezinembile ukusiza ekufinyeleleni indawo eqondile kanye nokucubungula, okuqinisekisa ikhwalithi yokucubungula.

4.Ukuhlolwa kobuso

Ikhwalithi yendawo ye-PCB ibalulekile ekusebenzeni komkhiqizo. Amalensi ezimboni angasetshenziswa ukuhlola indawo ukuze kuhlolwe ukuthi indawo ye-PCB iyisicaba, ayinamiklwebhe, ayinasici, njll.

Ngokusebenzisa izithombe ze-optical ezinembile kakhulu, amalensi ezimboni angathola amaphutha amancane ebusweni nezinkinga, futhi aziphathe futhi azilungise ngesikhathi esifanele ukuqinisekisa ikhwalithi yomkhiqizo.

Amalensi ezimboni asetshenziswa ekuhlolweni kwekhwalithi ye-PCB

5.Ukuhlaziywa kwezithombe

Amalensi ezimboniinganikeza amakhono okuthwebula izithombe anesinqumo esiphezulu sokubuka nokuhlaziya izingxenye ezincane, imigqa kanye namajoyinti e-solder kuma-PCB, okusiza ekuboneni izinkinga ezingaba khona zomklamo kanye nokukhiqizwa okunembile.

Ngaphezu kwalokho, amalensi ezimboni angahlanganiswa nezinhlelo zokucubungula izithombe ukuze kuqoqwe futhi kuhlaziywe idatha. Izithombe ezithathwe amalensi ezimboni zingasetshenziswa ekukhipheni idatha, ekuhlaziyeni nasekugcineni idatha ukusiza ekwenzeni ngcono izinqubo zokukhiqiza, ukuthuthukisa ukusebenza kahle kanye nokulawula ikhwalithi.

Imicabango Yokugcina:

UChuangAn wenze umklamo wokuqala kanye nokukhiqizwa kwamalensi ezimboni, asetshenziswa kuzo zonke izici zezicelo zezimboni. Uma unesithakazelo noma unesidingo samalensi ezimboni, sicela usithinte ngokushesha okukhulu.

Isikhathi sokuthunyelwe: Mashi-04-2025