Lilense tsa indasterili sebelisoa haholo. Ntle le lits'ebeliso tsa tsona tlhahlobong ea indasteri, tlhokomelo ea ts'ireletso, lisebelisoa tsa elektroniki tsa 3C le liindasteri tse ling, li boetse li sebelisoa haholo indastering ea PCB (Printed Circuit Board).

Litaelo tse tobileng tsa ts'ebeliso ea lilense tsa indasteri indastering ea PCB

Tšebeliso e tobileng ea lilense tsa indasteri indastering ea PCB e ka akaretsoa ka litsela tse latelang tse kholo:

1.Tlhahiso e iketsang

Lilense tsa indasteri tse kopantsoeng le litsamaiso tsa pono ea mochini li ka sebelisoa lisebelisoa tse iketsang meleng ea tlhahiso ea PCB, joalo ka liroboto tsa ho tjheseletsa tse iketsang, mechini ea ho beha, jj., ho fihlella ho lemoha, ho beha le ho sebetsana ka boiketsetso meleng ea tlhahiso ea PCB.

Lilense tsa indasteri li ka fana ka litšoantšo tse nang le tlhaloso e phahameng, tse nolofalletsang sistimi ea roboto ho tseba le ho sebetsana le tlhahisoleseling ka nepo le ka potlako joalo ka sebaka sa mapolanka a PCB le moralo oa likarolo, ka hona ho fihlella ts'ebetso e sebetsang ea tlhahiso e iketsang.

2.Teko le taolo ea boleng

Indastering ea PCB,lilense tsa indasterili sebelisoa haholo ho lemoha le ho hlahloba boleng le botšepehi ba liboto tsa PCB. Ka qeto e phahameng le ho hlaka ha lilense tsa optical, boleng ba manonyeletso a solder, maemo a likarolo, likoli le mefokolo ho li-PCB li ka bonoa ho netefatsa boleng ba sehlahisoa le botšepehi.

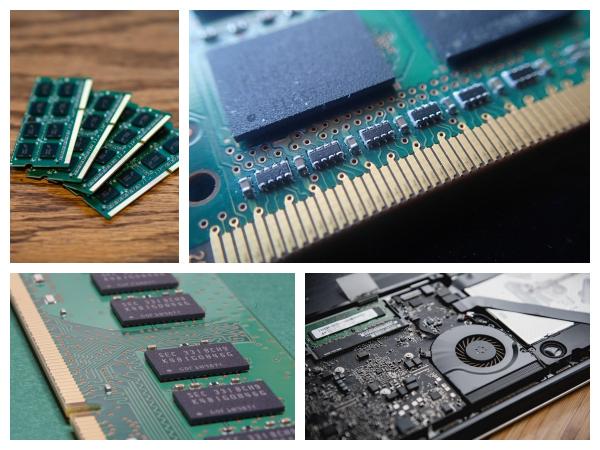

Lilense tsa indasteri li sebelisoa indastering ea PCB

3.Sebaka le tekanyo e nepahetseng

Ts'ebetsong ea tlhahiso ea indasteri ea PCB, lilense tsa indasteri li ka sebelisoa ho fumana likarolo le lintlha tsa khokahano ho PCB ka nepo, le ho li lekanya le ho li netefatsa ho netefatsa ho nepahala le ho nepahala ha ho kenngoa le ho hokahana ha likarolo.

Mohlala, lits'ebetsong tse kang ho phunya PCB le ho tjheseletsa menoana ea khauta, sebaka se hloka ho laoloa ka nepo. Lilense tsa indasteri li ka fana ka litšoantšo tse hlakileng le tse nepahetseng ho thusa ho fihlella boemo le ts'ebetso e nepahetseng, ho netefatsa boleng ba ts'ebetso.

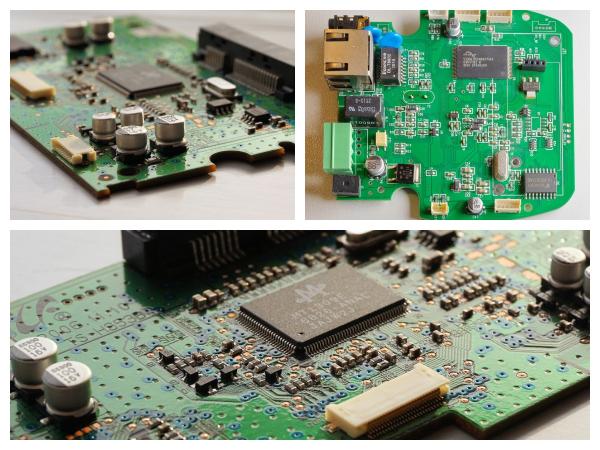

4.Tlhahlobo ea bokaholimo

Boleng ba bokaholimo ba PCB bo bohlokoa bakeng sa ts'ebetso ea sehlahisoa. Lilense tsa indasteri li ka sebelisoa bakeng sa tlhahlobo ea bokaholimo ho hlahloba hore na bokaholimo ba PCB bo bataletse, ha bo na mengoapo, ha bo na sekoli, jj.

Ka ho sebelisa litšoantšo tsa mahlo tse nepahetseng haholo, lilense tsa indasteri li ka lemoha liphoso tse nyane tsa bokaholimo le mathata, 'me tsa li sebetsana le ho li lokisa ka nako e loketseng ho netefatsa boleng ba sehlahisoa.

Lilense tsa indasteri li sebelisoa tlhahlobong ea boleng ba PCB

5.Tlhahlobo ea litšoantšo

Lilense tsa indasterie ka fana ka bokgoni ba ho nka ditshwantsho ka qeto e phahameng bakeng sa ho shebella le ho sekaseka dikarolo tse nyane, mela le manonyeletso a solder ho di-PCB, ho thusa ho hlwaya mathata a ka bang teng bakeng sa moralo le tlhahiso e nepahetseng.

Ho phaella moo, dilense tsa indasteri di ka boela tsa kopanngwa le ditsamaiso tsa ho sebetsana le ditshwantsho bakeng sa pokello le tlhahlobo ya data. Ditshwantsho tse nkuweng ke dilense tsa indasteri di ka sebediswa bakeng sa ho ntsha data, ho sekaseka le ho e boloka ho thusa ho ntlafatsa ditshebetso tsa tlhahiso, ho ntlafatsa bokgoni le taolo ya boleng.

Mehopolo ea ho Qetela:

ChuangAn e entse moralo oa pele le tlhahiso ea lilense tsa indasteri, tse sebelisoang likarolong tsohle tsa lits'ebetso tsa indasteri. Haeba u na le thahasello kapa u na le litlhoko tsa lilense tsa indasteri, ka kopo ikopanye le rona kapele kamoo ho ka khonehang.

Nako ea poso: Hlakubele-04-2025