Kuyesa kosawononga (NDT) ndi njira yoyesera yosawononga yomwe imayang'ana zinthu popanda kuwononga. Ndi njira yoyesera yofunika kwambiri m'mafakitale ndipo imagwira ntchito yofunika kwambiri pakukula kwa mafakitale.Magalasi a masomphenya a makinaamagwiritsidwa ntchito kwambiri popanga mafakitale; mawonekedwe awo apamwamba, kujambula kolondola, ndi mapangidwe apadera a kuwala zimakwaniritsa zosowa za kuwunika kwa mafakitale, ndipo kugwiritsa ntchito kwawo mu NDT n'kofunika kwambiri.

Mu mayeso osawononga, kugwiritsa ntchito magalasi owonera makina kumaphatikizapo, koma sikungokhala kokha, izi:

1.Kuzindikira chilema pamwamba

Mu mafakitale opanga zinthu, magalasi owonera makina amagwiritsidwa ntchito kwambiri poyang'ana pamwamba pa zinthu monga zitsulo, pulasitiki, galasi, ndi zoumbaumba kuti aone ngati pali zolakwika monga mikwingwirima, ming'alu, ma pores, ndi zinthu zina, kuonetsetsa kuti khalidwe la malonda likukwaniritsa zofunikira. Kudzera mu luso lawo lojambula zithunzi zowoneka bwino komanso zosapotoza, magalasi owonera makina amatha kuwonetsa bwino zolakwika izi, kupereka chithandizo chodalirika cha deta kuti zithunzi zikonzedwe ndi kusanthula pambuyo pake.

Mwachitsanzo, lenzi yowonera makina yowoneka bwino kwambiri yolumikizidwa ndi maikulosikopu kapena kamera yothamanga kwambiri imatha kujambula zolakwika za micron, monga kuzindikira malo olumikizirana osalimba, ma short circuits, ndi kusalingana bwino kwa zigawo pa ma PCB board, kapena mikwingwirima ndi zodetsa pamalo a semiconductor wafer.

2.Kuyang'ana zolakwika zamkati/kapangidwe kake

Pogwiritsa ntchito magalasi owonera makina pamodzi ndi njira zapadera zowunikira, n'zotheka kuwona kapangidwe ka mkati mwa zinthu kapena zolakwika zake. Izi zimathandiza kuzindikira zolakwika zobisika monga ma pores, delamination, ndi ming'alu mu castings, zinthu zophatikizika, ndi malo olumikizirana.

Mwachitsanzo, imatha kuzindikira thovu, zinyalala, ndi ming'alu mkati mwa galasi, mapulasitiki, ndi zinthu zowunikira (monga mabotolo agalasi ndi zinthu zowunikira). Kudzera mu kujambula kwa backlight kapena laser scanning, imatha kuzindikira delamination kapena debonding mkati mwa zinthu zambiri (monga zinthu zozungulira aerospace).

Magalasi owonera makina nthawi zambiri amagwiritsidwa ntchito pozindikira zolakwika za chinthu

3.Kuyeza molondola kwa miyeso

Magalasi a masomphenya a makinaamagwiritsidwa ntchito nthawi zambiri poyesa molondola kukula kwa zinthu komanso kutsimikizira kupirira kwa mawonekedwe ndi malo a zinthu, monga makulidwe a semiconductor wafer, kuzungulira kwa bearing roller, ndi mawonekedwe ndi mtundu wa chinthucho. Mwachitsanzo, pa mizere yodzaza chakudya, magalasi owonera makina angagwiritsidwe ntchito kuwona kutsekedwa kwa zipewa za mabotolo ndi kulondola kwa zilembo, kuonetsetsa kuti zinthuzo ndi zabwino komanso zotetezeka.

4.Kuyang'anira kupanga zokha

Kugwiritsa ntchito magalasi owonera makina poyesa kosawononga kumaphatikizaponso kuyang'anira kupanga kokha, komwe nthawi zambiri kumagwiritsidwa ntchito poyesa zolakwika zokha pamizere yopangira mwachangu, monga kuyang'anira zokha ma chips amagetsi, mabatire a lithiamu, ma seams a weld agalimoto, ndi zina zotero. Mwachitsanzo, lenzi yojambulira mzere ingagwiritsidwe ntchito ndi kamera yojambulira mzere kuti ione zolakwika pamwamba pa mzere wachitsulo kuti ipezeke bwino kwambiri.

5.Kuyang'anira mapaipi/malo otsekedwa

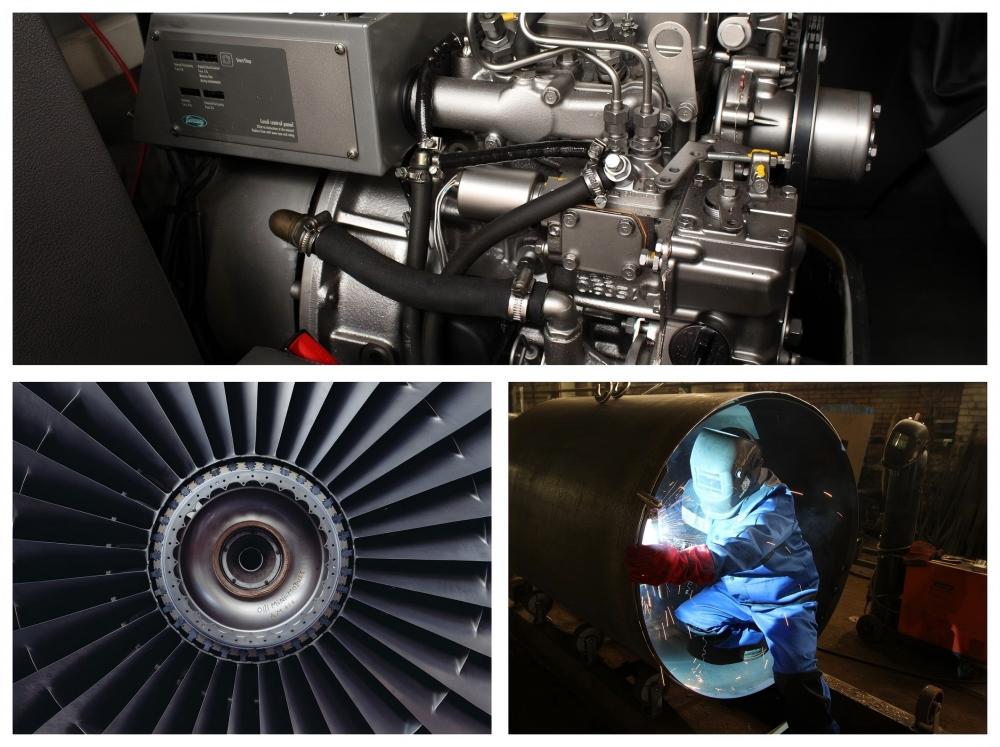

Magalasi owonera makina amagwiritsidwa ntchito mu ma endoscope a mafakitale kuti azindikire zolakwika mkati mwa nyumba zovuta, monga zolakwika zobisika mkati mwa injini, makoma a mapaipi, kapena ma weld. Mwachitsanzo, ma endoscope a makanema a mafakitale amagwiritsa ntchito ma probe ataliatali komanso osinthasintha kuti alowe mkati mwa zida, kutumiza zithunzi zapamwamba nthawi yeniyeni, zomwe zimathandiza kuyesa kosawononga popanda kusokoneza.

Magalasi owonera makina angagwiritsidwe ntchito kuzindikira zolakwika mkati mwa nyumba zovuta

6.Kuzindikira pansi pa mikhalidwe yapadera

Magalasi owonera makina angagwiritsidwenso ntchito poyang'ana patali m'malo ovuta monga kutentha kwambiri, kuthamanga kwambiri, ndi kuwala kwa dzuwa, kuphatikizapo ma reactor a nyukiliya ndi mapaipi oyeretsera mafuta, zomwe zimathandiza kuwunika komwe kumakhala kovuta kuchita pogwiritsa ntchito njira zachikhalidwe.

Mwachitsanzo, magalasi oteteza kutentha kwambiri angagwiritsidwe ntchito kuyang'ana zolakwika pamwamba pa zitsulo mkati mwa uvuni zopangira zitsulo kapena kuwonongeka kwa malo otsekera zida pansi pa kupanikizika kwakukulu. Mwa kuyika magalasi ang'onoang'ono owonera makina pa ma endoscope, dzimbiri ndi ming'alu ya weld pamakoma amkati mwa mapaipi zimatha kupezeka, monga m'mapaipi a petrochemical ndi zotengera za nyukiliya.

Powombetsa mkota,magalasi owonera makina, ndi ubwino wawo wa kujambula zithunzi zowoneka bwino kwambiri, kuyeza kosakhudzana ndi kukhudzana, komanso kugwira ntchito bwino nthawi yeniyeni, zakhala ukadaulo wofunikira kwambiri pakuwongolera khalidwe la mafakitale amakono. Phindu lawo lalikulu lili pakukweza khalidwe la kujambula zithunzi ndikuwerengera zambiri za zolakwika, motero kukulitsa kudalirika kwa kuwunika kwa mafakitale ndikuchita gawo losasinthika pakuyesa kosawononga.

Maganizo Omaliza:

ChuangAn wapanga kale mapulani ndi kupanga magalasi owonera makina, omwe amagwiritsidwa ntchito pazinthu zonse zokhudzana ndi makina owonera. Ngati mukufuna kapena mukufuna magalasi owonera makina, chonde titumizireni uthenga mwamsanga.

Nthawi yotumizira: Disembala-12-2025